From Gate to Ball: Understanding Different Types of Valves for Home and Commercial Use

- SURESH K

- Nov 11, 2025

- 5 min read

Valves may seem like small, simple parts in your plumbing or mechanical system, but they play a critical role in controlling water, gas, and other fluid flows. Whether it’s a small tap in your home kitchen or a complex network in a commercial plant, choosing the right valve can mean the difference between smooth operation and costly system failure.

In this blog, we’ll explore the different types of valves commonly used in both residential and commercial settings—their design, purpose, advantages, and where they best fit.

1. What Is a Valve?

A valve is a mechanical device that controls, regulates, or directs the flow of a fluid—usually water, gas, or air—by opening, closing, or partially obstructing passageways.

Every plumbing or mechanical system depends on valves to:

Start or stop fluid flow

Prevent backflow

Regulate pressure

Protect equipment and users

Valves can be manual, where a person turns a handle or lever, or automatic, controlled by sensors or actuators.

2. Common Types of Valves and Their Functions

Let’s break down the most widely used valve types you might encounter—from the simple gate valve in your home to the high-precision control valve in industrial systems.

a) Gate Valve

Function: To start or stop water flow (not for flow regulation).

Gate valves use a metal gate or wedge that moves up and down inside the valve body. When fully open, the gate lifts to allow unobstructed flow; when closed, it seals tightly.

Where used:

Main water supply lines

Irrigation systems

Industrial pipelines

Advantages:

Minimal flow restriction when open

Simple design and long lifespan

Limitations:

Not suitable for throttling (can cause damage if partially open)

Slower to operate compared to ball valves

b) Ball Valve

Function: Quick on/off control.

This type uses a rotating ball with a hole through its center. When aligned with the pipe, flow passes freely; when rotated 90°, flow stops instantly.

Where used:

Home water lines

Industrial and chemical systems

HVAC and compressed-air systems

Advantages:

Quick quarter-turn operation

Tight sealing, even after years of use

Durable and low maintenance

Limitations:

Not ideal for throttling applications (risk of seat damage)

Ball valves are the most popular for residential and light commercial use because they are reliable, affordable, and easy to operate.

c) Globe Valve

Function: Flow regulation and throttling.

A globe valve features a movable disk and stationary ring seat. The disk moves perpendicularly to the seat, allowing precise flow control.

Where used:

Cooling water systems

Boiler and feedwater lines

Chemical processing plants

Advantages:

Excellent for flow control

Tight shut-off capability

Limitations:

Higher pressure drop compared to gate or ball valves

More complex structure and costlier maintenance

d) Check Valve

Function: Prevents backflow in a piping system.

A check valve allows fluid to flow in one direction only. When flow reverses, the valve automatically closes, preventing contamination or system damage.

Where used:

Pump discharge lines

Water heaters and booster systems

Sewage and wastewater systems

Advantages:

Fully automatic—no manual operation needed

Protects pumps and equipment from reverse flow

Limitations:

Requires correct installation orientation

May cause water hammer if not properly selected

e) Butterfly Valve

Function: Flow isolation and throttling.

Butterfly valves use a flat circular disc that rotates inside the pipe. When the handle turns, the disc rotates on a shaft to open or close the flow.

Where used:

Large-diameter pipelines

Fire protection, HVAC, and chemical systems

Advantages:

Compact and lightweight

Easy to install and operate

Cost-effective for large pipes

Limitations:

Less tight shut-off compared to ball valves

Not ideal for high-pressure systems

f) Pressure-Reducing Valve (PRV)

Function: Regulates and maintains safe downstream pressure.

PRVs automatically reduce high inlet pressure to a safe, consistent outlet pressure.

Where used:

Domestic water supply systems

High-rise building plumbing

Industrial process lines

Advantages:

Prevents pipe damage and leaks due to high pressure

Ensures stable water flow and saves water

Limitations:

Requires occasional maintenance to prevent clogging or wear

g) Solenoid Valve

Function: Electrically controlled valve for automatic systems.

Solenoid valves use an electromagnetic coil to open or close the valve when energized.

Where used:

Irrigation systems

HVAC and air-conditioning units

Fire-fighting systems and automation panels

Advantages:

Precise remote control

Fast response time

Easily integrated with sensors or PLCs

Limitations:

Requires electricity to function

Coil failure can cause malfunction if not maintained

3. How to Choose the Right Valve

Selecting the right valve depends on several key factors:

Criteria | Considerations |

Purpose | Is it for on/off control, regulation, or safety? |

Medium | Water, gas, air, oil, or chemicals? |

Pressure & Temperature | High-pressure systems need stronger materials like stainless steel. |

Size & Space | Compact options like ball or butterfly valves suit tight spaces. |

Operation | Manual, electric, or pneumatic? |

Budget | Brass and PVC are economical; stainless steel offers longevity. |

For example, in home plumbing, a ball valve is ideal for quick shut-off, while in commercial buildings, a butterfly valve handles larger diameters efficiently.

4. Material Matters: Brass, PVC, or Stainless Steel?

Choosing the right material ensures durability and safety:

Brass valves: Common in domestic water systems. Resistant to corrosion, cost-effective, and long-lasting.

PVC (Plastic) valves: Lightweight and ideal for low-pressure or chemical applications.

Stainless steel valves (SS304 or SS316): Used in food, pharmaceutical, and industrial systems for corrosion resistance and strength.

Cast iron valves: Suitable for large-scale, heavy-duty applications.

5. Maintenance Tips for Longer Valve Life

Even the best valve can fail if neglected. Here’s how to keep them working efficiently:

✅ Operate periodically: Move manual valves occasionally to prevent seizing.✅ Check for leaks: Small drips can indicate seal wear or seat damage.✅ Lubricate moving parts: Especially in older gate or globe valves.✅ Replace worn seals or washers: Don’t wait for leaks to worsen.✅ Inspect for corrosion: Especially in outdoor or high-humidity installations.

A well-maintained valve can last 10–20 years or more depending on use and environment.

6. Real-World Example: Domestic vs. Commercial Application

Home Use:

Ball valves for kitchen and bathroom shut-offs

PRVs for incoming main water supply

Check valves for water heaters and pumps

Commercial Use:

Gate or butterfly valves for mainline isolation

Globe valves for flow control in mechanical systems

Solenoid valves for automation and control systems

By matching valve type to application, both homes and commercial facilities achieve better safety, water efficiency, and performance reliability.

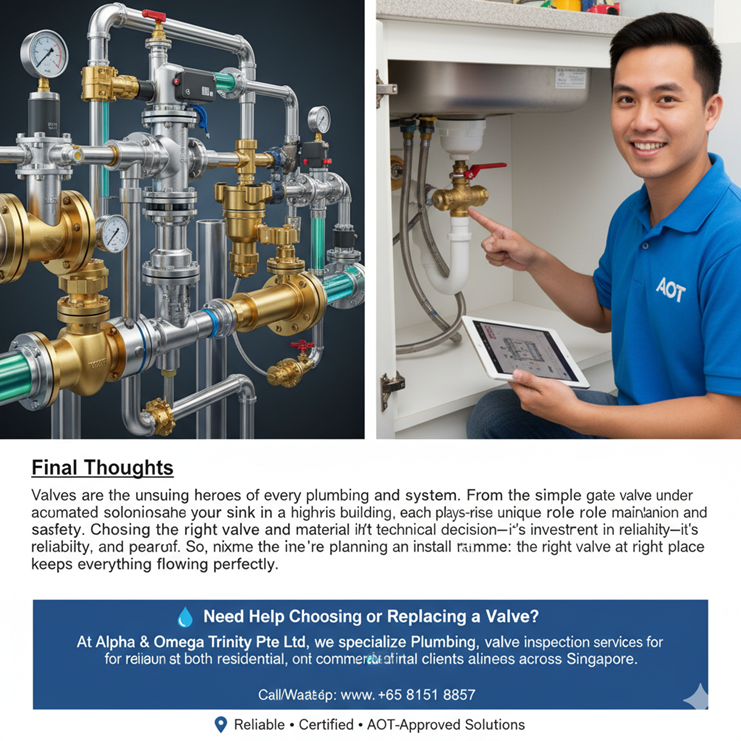

7. Final Thoughts

Valves are the unsung heroes of every plumbing and mechanical system. From the simple gate valve under your sink to the automated solenoid valves in a high-rise building, each plays a unique role in maintaining smooth operation and safety.

Choosing the right valve type and material isn’t just a technical decision—it’s an investment in reliability, efficiency, and peace of mind.

So, next time you’re planning an installation or maintenance project, remember: the right valve at the right place keeps everything flowing perfectly.

Need Help Choosing or Replacing a Valve?

At Alpha & Omega Trinity Pte Ltd, we specialize in plumbing, valve inspection, and replacement services for both residential and commercial clients across Singapore.

💧 Call/WhatsApp: +65 8151 8857🌐 Website: www.aotrinitysg.com📍 Reliable • Certified • AOT-Approved Solutions

Comments